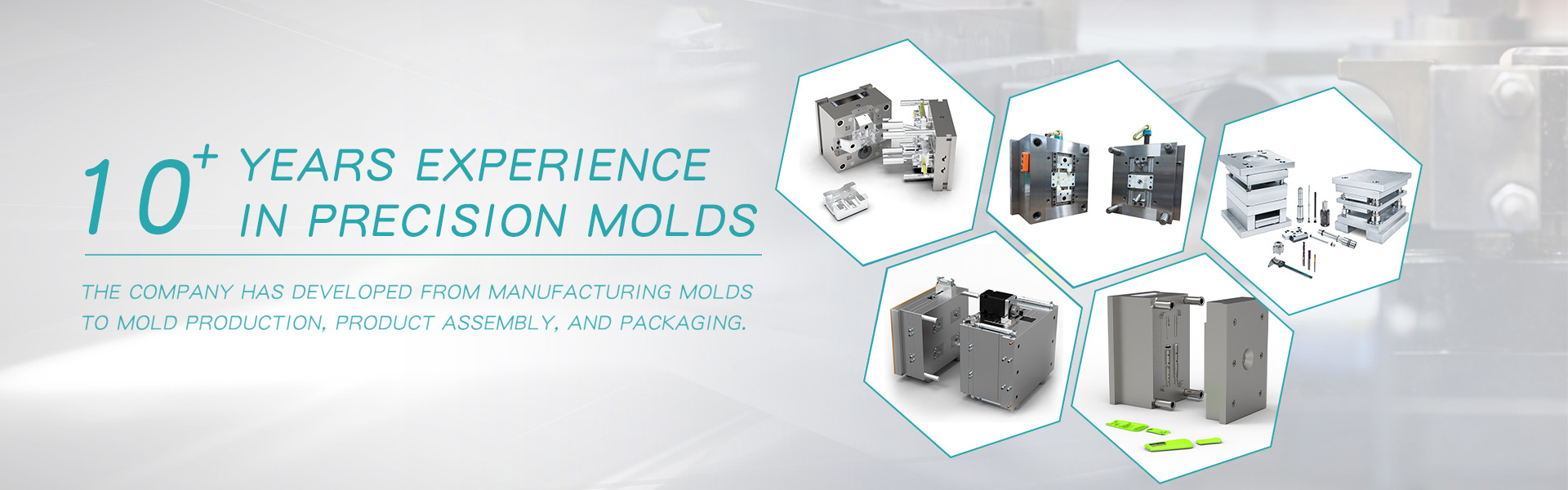

【Company Profile】

Aosaixiang Precision Mold Co., Ltd. iISO 9001:2000 kambani yakasimbiswa inopa yakazara-sevhisi jekiseni mold dhizaini uye kusimudzira mold, kunyatsogadzirisa mold uye kugadzirwa kwezvikamu. Isu tave tichibatanidzwa muindasitiri yechaiyo mold kwemakore mazhinji uye tine ruzivo rwakapfuma mukugadzira mold, kunyanya kubata mukufa-kukanda mold uye akajairwa jekiseni mold. Isu tinopawo kukosha-akawedzera masevhisi kuvatengi vari mumaindasitiri ekurapa, emotokari, evatengi, emagetsi uye ekuvaka, senge akasanganiswa ekurongedza uye sub-assembly.

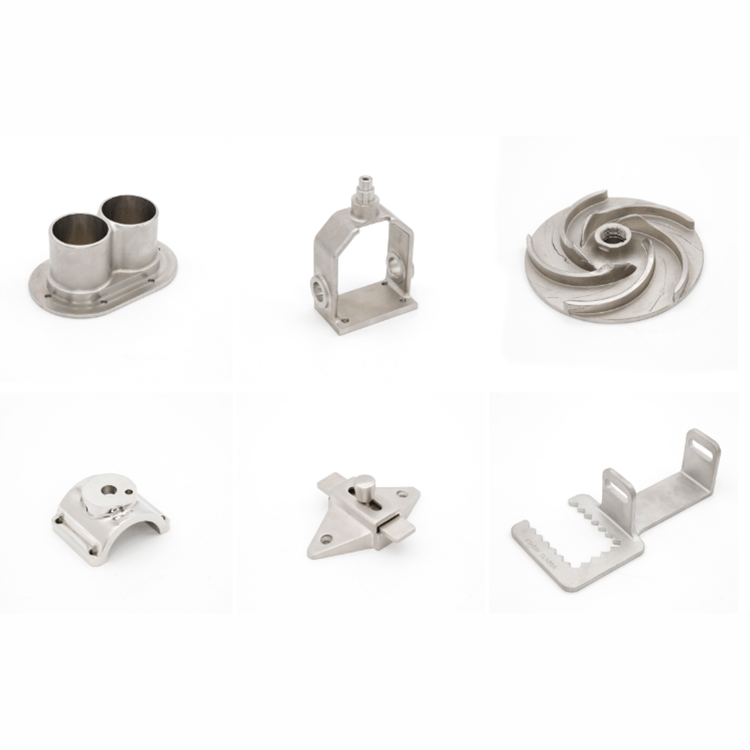

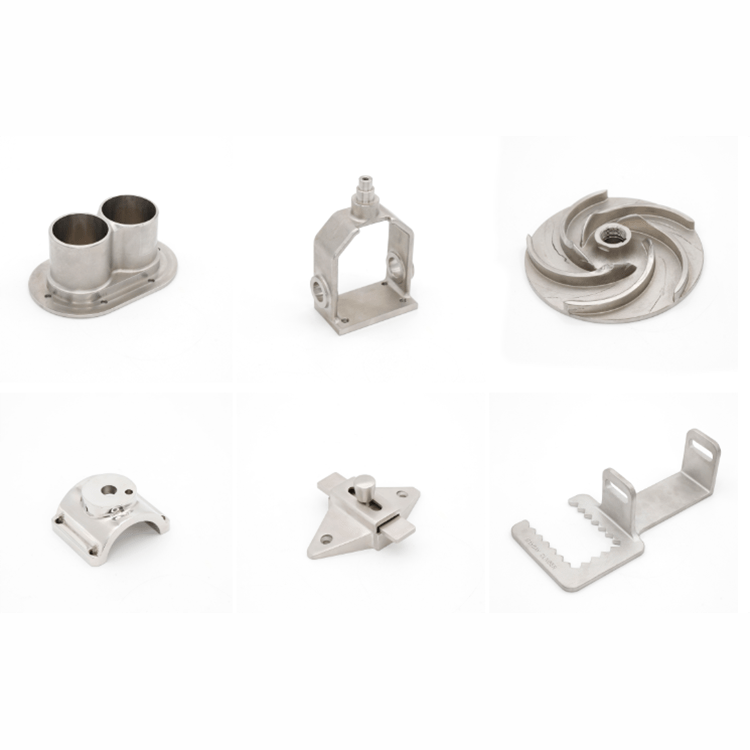

【Die-casting chigadzirwa range】

Aluminium inofa-casting midziyo yemumba.

Aluminium die-casting automotive products

Aluminium die-casting tool products

Sand casting wall thick products

Industrial iron parts products

Industrial iron casting tool

Ap Aerospace, kurima, kuvaka, mota, makemikari, zvemagetsi, maturusi emuchina, ngarava, zvekurapa, zvechiuto, uye oiri negasi. full-service customized mugadziri wehombe-capacity uye high-pressure die-casting.

2. Alloys anoshandiswa anosanganisira aruminiyamu ne zinc.

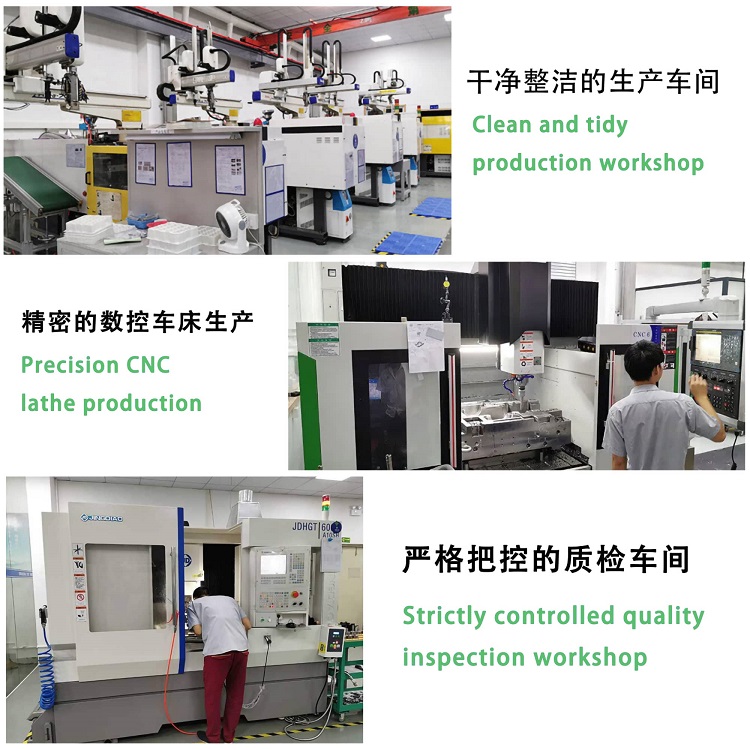

3. Zvinogona zvinosanganisira CNC lathe basa, EDM, horizontal CNC machining, pallet CNC machining. , vertical CNC machining, waya yekucheka machining, yakaderera / yepakati vhoriyamu kugadzirwa uye prototypes. Mamwe masevhisi anosanganisira kusangana, kukoira, engineering, kuongorora uye kugadzirisa. Masevhisi ekupukuta anosanganisira kukwenenzvera, kupenda, electroplating, kuchenesa, kupedzisa, kuputika kwejecha, kukwenenzvera, kupotera hupfu uye anodizing.

4. Sangana neANSI neASME mwero.

5. Psa chitupa chisingatungamiri.

Gadziriro

1.Aluminium alloy die casting:A360 / A380 / A390D / ADC10 / ADC12 / ZL110,ZL101,102,114,etc.

2.Zinc alloy die casting:ZDC1 / ZDC2 / Zamak 3 / Zamak5 / ZL4-1, etc.

3.CNC machining:6061 6063

| Mold kugadzira: kubva pakugadzira kusvika pakugadzira mold uyezve kusvika pakupihwa kweanokwanisa samples

|

Mechanical

|

|

|

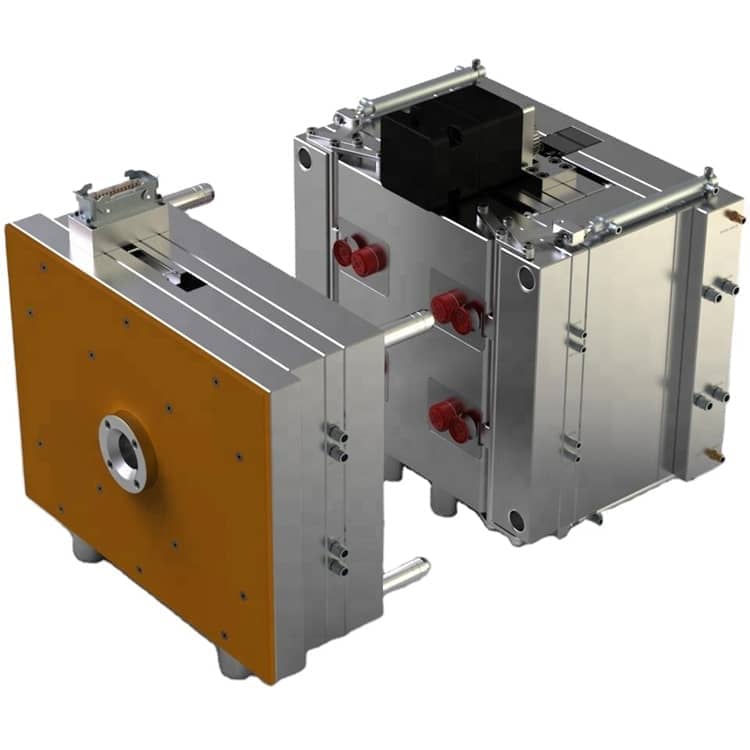

1.Cold Chamber Die Casting Machine: 180T / 280T / 500T / 800T / 1250T

|

|

|

2.Hot chamber die casting machine:58T / 88T / 168T

|

|

|

3. CNC centre, CNC turning, CNC lathe, electronic pulse, waya yekucheka muchina, milling, drilling, kugaya.

|

| Surface treatment and polishing

|

Shot blasting, sandblasting, painting, powder coating, anodizing, chrome plating, nickel plating, zinc plating, electrophoresis, passivation, makemikari coating, etc.

|

|

|

Software

|

|

|

Pro / E,UG,Solidworks,Auto CAD,PDF

|

| Applications

|

1. Mota uye zvishandiso zvemudhudhudhu: chivharo cheinjini, silinda musoro, brake pad, shaft, clutch, nezvimwe.

|

| 2. Zvikamu zvemwenje: redhiyeta, kapu yemwenje, mumvuri wemwenje, LED/rambi remumugwagwa/zvishongedzo zvemwenje, nezvimwewo.

|

3. Magonhi nemahwindo: gonhi (hwindo) mubato/hinge/kiyi, kumira kwegonhi, simbi yegirazi, nezvimwewo.

|

| 4. Zvikamu zvemagetsi: zvinobatanidza, mabhokisi epanosangana runhare, mabhokisi epanosangana asingapindi mvura, nezvimwewo.

|

5. Furnicha Hardware accessories: makumbo esofa, mabhuraketi efenicha, zvishongedzo zvemasitepisi, zvekushongedza nezvimwe.

|

|

|

6. Zvigadzirwa zvemaindasitiri: kudzora vharafu dzimba, maturusi epneumatic, chivharo cheinjini, zvikamu zvezviridzwa, nezvimwe.

|

|

|

7. Zvimedu zvemuchina: vharafu yemagetsi, ndiro yepasi, ndiro yekugumisira, mativi epropeller, etc.

|

|

|

【Sei tinosarudza isu?】

|

|

|

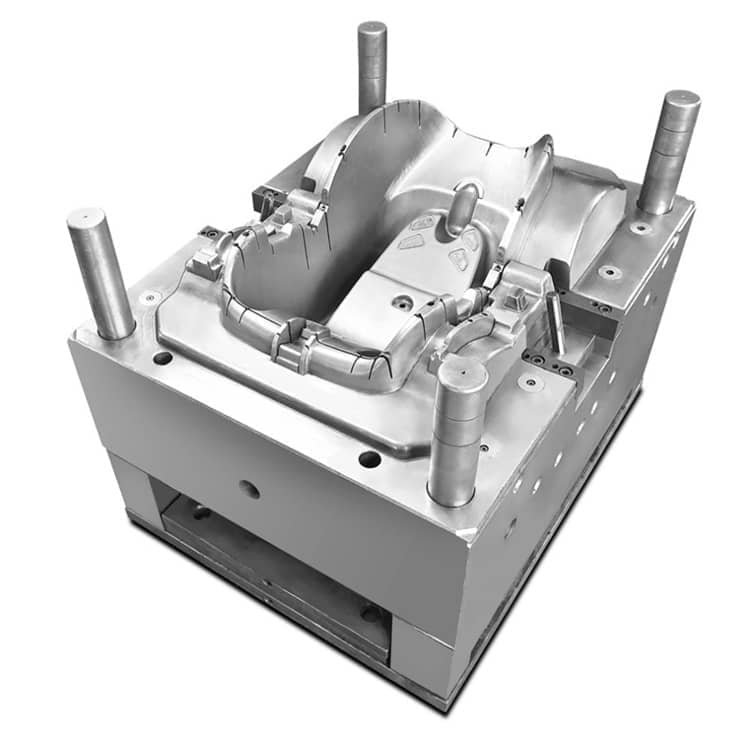

Aosaixiang Precision Mold Co., Ltd. inyanzvi mukugadzirwa kwezvikamu zvepurasitiki zvekuumbwa nemazvo. kuisa, kudhinda zvidimbu zvemold, mativi asiri akajairwa eraundi, uye masimende ecarbide parts.

|

|

|

Zvigadzirwa zvedu zvinoshandiswa munzvimbo dzakawanda, senge mould dzepurasitiki dzakanyatsojeka, mold dzekutsikisa, mold dzemotokari, mold dzekurapa, mold dzekubatanidza nezvimwe zvikamu zveotomatiki. . Tinokwanisa kugadzira huremu kubva pazero kusvika pamatani makumi maviri.

|

|

|

Tinotarisa pakugadzira majekiseni epurasitiki emhando yepamusoro uye mould, uye tinokwanisa kugadzira zvikamu zvinopfuura makumi mashanu kusvika ku100,000 zvakapedzwa nemapurasitiki akasiyana.

|

Takawana ruzivo rwakapfuma rwehunyanzvi. , tekinoroji, kushambadza uye sevhisi mukugadzira zvikamu zve mold.

Takawanawo kuzivikanwa nerutsigiro kubva kune vatengi pasi rese.

Kuburikidza nekuongorora kwezvinhu zvemhando yepamusoro uye maitiro emhando yepamusoro, tinogona kuve nechokwadi chekuti maturusi ako nezvikamu zvinopfuura zvaunotarisira.

FAQ

Q1. Iwe uri mugadziri? Chii chandingatenge kubva kuOsaixiang?

A: Isu tiri vagadziri ve mold, tichipa yakazara-sevhisi jekiseni mold dhizaini uye kusimudzira mold, kunyatsogadzirisa mold uye kugadzirwa kwezvikamu. Zvigadzirwa zvedu zvinosanganisira: mapurasitiki ekuumba, hardware molds, turusi jecha rekukanda molds, kufa-casting molds, silicone molds, uye chaiyo zvikamu zvigadzirwa zvinosanganisira: zvigadzirwa zvepurasitiki, zvigadzirwa zvealuminium kufa-casting, iron die-casting products, hardware products, silicone products, tinokwanisawo kupa Customized mold uye chigadzirwa basa.

Q3. Ndeupi rudzi rwemuchina wekugadzira?

A: Inogadzirwa neCNC machining, laser yekucheka, stamping, jekiseni rekugadzira uye chikamu mafaera, uye inogona zvakare kurapwa pamusoro.

Q4. Nzira yekuva nechokwadi chekuti kunaka kwacho? Ndeipi nguva yekutumira?

A: Zvichienderana nezvikamu zvechigadzirwa uye huwandu, nguva yekuendesa ndeyemazuva 7-50. Unogona kutitumira email zvakananga kuti undiudze chigadzirwa uye huwandu hwaunoda, uye isu tichakupindura iwe. mumaawa makumi maviri nemana.

Q2. What can I buy from Osaixiang?

A: We are a mold manufacturer, providing full-service injection mold design and mold development, precision mold processing and parts production. Our products include: plastic molds, hardware molds, tool sand casting molds, die-casting molds, silicone molds, and precision parts products including: plastic products, aluminum die-casting products, iron die-casting products, hardware products, silicone products, we can also provide Customized mold and product service.

Q3. What is the type of manufacturing machine?

A: It is manufactured by CNC machining, laser cutting, stamping, injection molding and part files, and can also be surface treated.

Q4. How to ensure the quality?

A: We have a dedicated quality control department responsible for quality control before shipment, and a final inspection is always carried out before shipment.

Q5. What is the delivery time?

A: Depending on the product parts and quantity, the delivery time is 7-50 days.You can send us an email directly to tell me the product and quantity you need, and we will reply you within 24 hours.

English

English